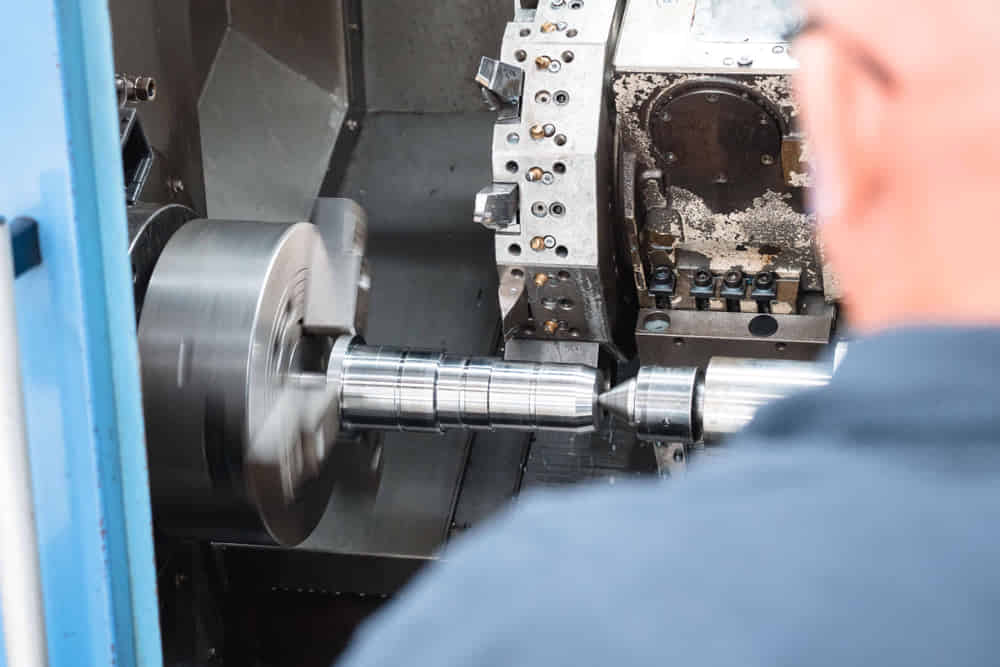

KJE specialises in CNC Machining and Fabrication services, creating custom-made products to meet our clients’ unique engineering needs all under one roof.

We utilise the latest technologies, design expertise, and manufacturing techniques to stay at the cutting edge of our industry.

One of the key benefits of CNC Machining is the ability to produce complex geometries that would be difficult or impossible to achieve using traditional manufacturing techniques.

CNC machining often allows for faster turnaround times and lower costs, compared to other manufacturing methods.

At Kerry Jones Engineering we have employed experienced CNC Machinists who are experts in their field. Along with using quality machinery, we are able to produce incredibly complex parts to exacting measurements, within an appropriate time frame.

Fabrication is the process of creating a product or structure by cutting, bending, and assembling and joining raw materials.

Our services in this area include large production fabrication runs, one off fabrication products, cutting and rolling steel plate, and structural fabrication. Our customers bring a wide range of jobs for us to fabricate and we are always up for the challenge.

Due to our ability to process all work internally, we can ensure that the highest levels of quality control are upheld.

We work to your design model specifications, for review and approval.

The manufacturing process begins. We cut and shape the material according to your design specifications to create the final product.

We perform internal quality control checks to ensure that the final design meets industry standards and drawing specifications. We can offer site delivery, assembly and installation services as needed.

Get in touch with our friendly team to discuss your project.

Initial Consultation

We consult with you to discuss the scope of your project and provide guidance on the design and material choices.